Brooklyn Health Center

Brooklyn, NY

| DigitalDistinctions® Pattern Guide | |||

|---|---|---|---|

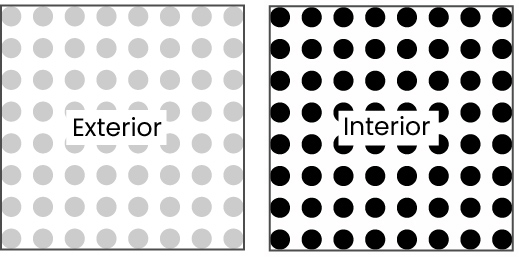

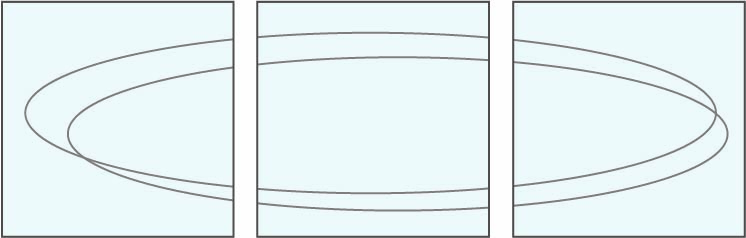

| Maximum Size | Pattern Type | Maximum Coverage / Sq. Ft. | Ceramic Enamel Color |

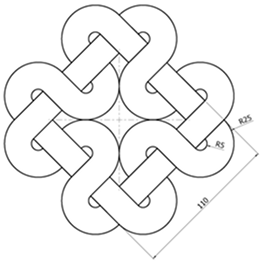

| Dimensions up to

130″ x 236″

(3297mm x 5994mm) —————————————– Unit size up to 213 Sq Ft (19.79 M2) | Full Coverage or Pattern (Minimum object or space size = 1/16″) | 100% | All DigitalDistinctions® Ink | All pattern types are available with Low-E coatings on the same surface. |