Specifying Printed Glass

Images may be applied to any surface except the exterior (#1) surface. A Low-E coating can be applied to the same surface as the printing. Units with printing should be utilized in applications where the printed surface is protected from exterior elements. The units should not be installed in applications where the printed surface will be exposed to an outdoor environment.

Printing to Edge of Glass

Silkscreen printing, in combination with a Low-E coating, does not require a clear, enamel-free border and can be printed to the edge of the glass.

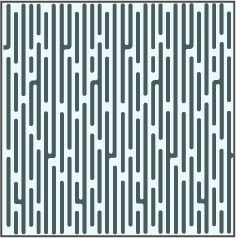

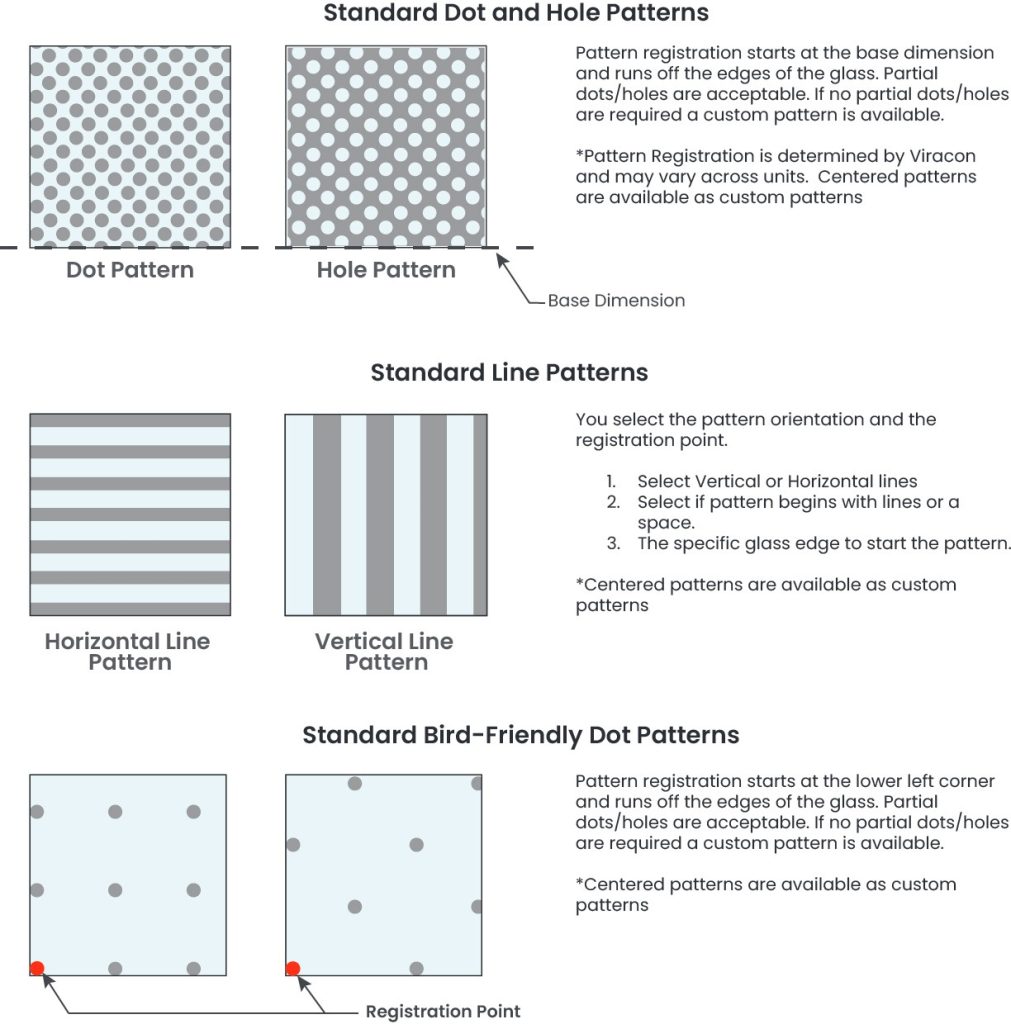

Standard Silkscreen Pattern Orientation and Registration

The orientation defines the direction of the pattern, such as horizontal lines or vertical lines. Registration identifies where to start the pattern. Below are the standard orientation and registration points for standard silkscreen patterns. Anything not shown below is considered a custom pattern and is subject to additional charges.

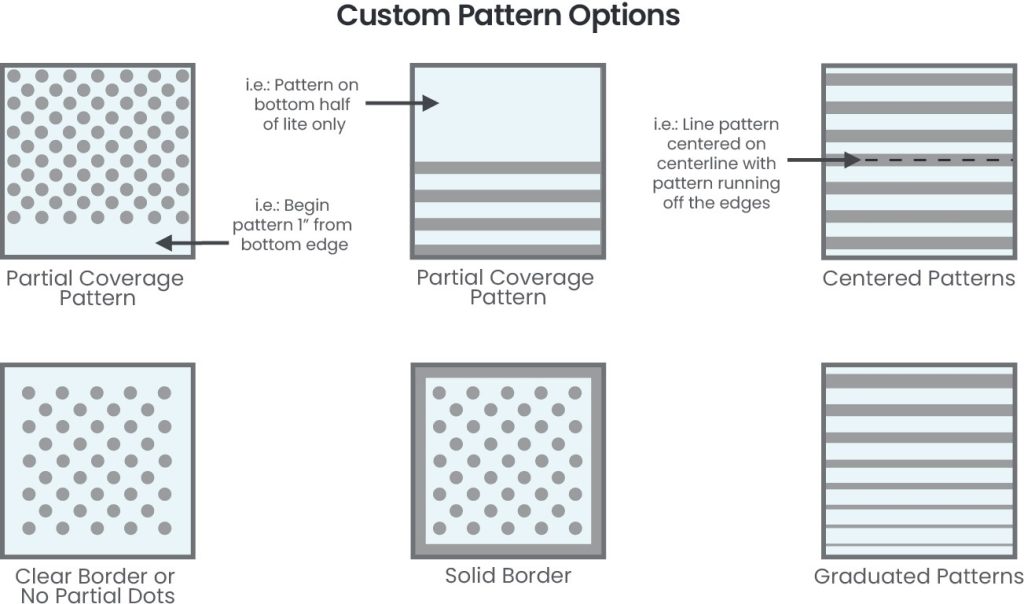

Custom Silkscreen Pattern Options

The following options are available with custom patterns, additional charges will apply.

Moiré

Placing a pattern or image on two surfaces within an insulating unit is feasible however extreme caution should be taken during the design process to minimize the potential for a moiré pattern to appear. Moiré is an optical phenomenon that typically appears as a wavy, rippled or circular pattern. It is formed when two regularly spaced, non-aligned patterns overlap. Moiré is not a defect in the glass or the printing process but rather a pattern formed by the eye. For additional information, please review Viracon’s

Ceramic Enamel and Ink Visual Characteristics Tech Talk.