Recommendations in the current edition of the Glass Association of North America (GANA) Glazing Manual along with the recommendations provided below, should be followed when designing with, and installing, our glass products. Viracon’s limited warranties are based, in part, on the glazing recommendations found in the GANA Glazing Manual.

- Utilize the appropriate glazing system components.

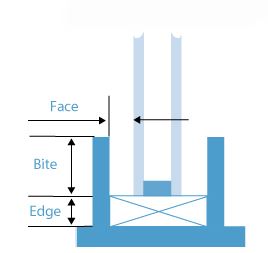

- Provide adequate clearances for the glass.

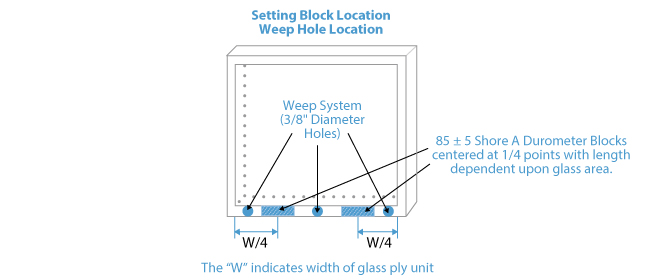

- Arrange for necessary glazing system drainage, weep.

- Ensure the framing system provides structural support and allows the glass to ‘float’ within the frame.

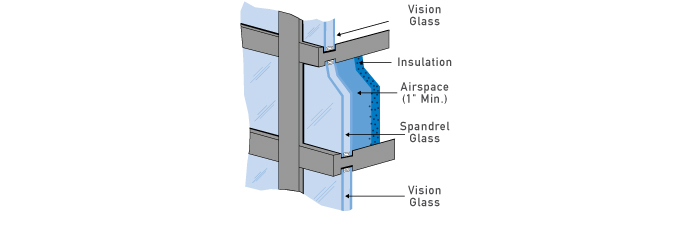

- For spandrel glass, provide space behind the glass to ensure no glass to insulation contact.

Glazing System Components and Clearances

Viracon requires that only 100% silicone setting blocks be used for all types of glazing systems. The blocks should have a durometer hardness of 85±5. They should also be centered at quarter points and be 1/16" (1.6 mm) less than the channel width. Setting blocks should be 0.1" in length for each square foot of glass area but never less than 4" in length. For additional recommendations, contact the appropriate gasket or framing manufacturer.

Viracon specifies that edge blocks or anti-walk blocks be used for dry glazed systems. Viracon also specifies that edge blocks be silicone and have a Shore-A Durometer hardness of 60 ±5 and be a minimum of 4” in length. They should be installed in the vertical channel with a 1/8” (3mm) clearance between glass edge and block. This will limit lateral movement of the glass. Inadequate edge clearances can cause glass breakage as a result of glass-to-frame contact.

Recommended Clearances

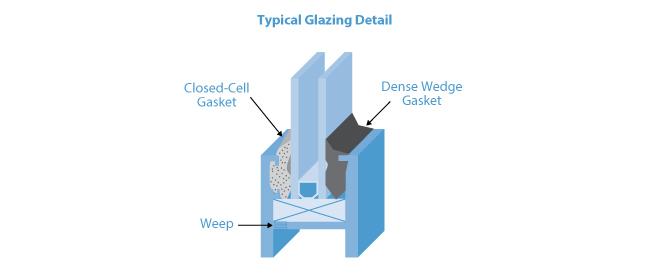

Glazing System Drainage

The edges of laminated, insulating, and spandrel glass should not be exposed to water or moisture vapor for extended periods of time. Exposure of the glass to moisture vapor or liquid water for extended periods will ultimately result in seal failure, coating deterioration, sealant deterioration, or de-lamination. Viracon requires either a positive weather seal, or an adequate weep system to prevent this occurrence. The effectiveness of the weep system or weather seal depends on the design, workmanship, engineering, and mock-up verification testing completed by the glazing manufacturer, installer, or designer. Responsibility for the weep system and its performance is the responsibility of those parties or others, and is not the responsibility of Viracon.

Framing Support and Deflection

The framing system must be designed to provide structural support to the glass and essentially allow the glass to float within the frame. The following framing tolerances are required:

- Deflection of the framing members under design loads must not exceed the length of the span divided by 175.

- Deflection of the horizontal sill member due to the weight of the glass should not exceed 1/8" nor should the deflection decrease the head clearance of the panel below by more than 25%.

- Twist of the horizontal sill member between the ends and center of each span, due to the weight of the glass, must be limited to one degree.

- Bow must not exceed 1/16" in any four foot length of the framing.

- Squareness must be controlled to 1/8" difference in the lengths of the diagonals.

- Offset of adjoining members must not exceed 1/32" at the corners.

Laminated Glass Railings

When utilizing a laminated glass railing, review GANA’s Glass Informational Bulletin GANA 09-0417, Use of Laminated Glass in Railing Systems. It is especially important to refrain from using cement-based grouts as they may be incompatible with laminated glass. Viracon’s warranties do not cover incompatibility.

Spandrel Glass

Viracon architectural products carry limited warranties. Failure to adhere to the following guideline for spandrel glass will void its warranty. Viracon does not recommend or warrant applications in which insulation is applied directly to the glass. Insulation should be installed with a 1" space between the glass and insulation.

Structural Silicone Glazing

Structural silicone glazing uses silicone sealant on one or more sides of the insulating unit for the structural transfer of loads from the glass to its perimeter support system and retention of the glass in the opening. When structurally glazed, the framing system is typically not visible on the exterior facade along the structurally glazed sides.

The sightline for insulating glass used in a structurally glazed application must be calculated based on the unit size and design loads in order to appropriately support the insulating unit and exterior glass ply. Sightlines are calculated based on ASTM C1249 Standard Guide for Secondary Seal for Sealed Insulating Glass Units for Structural Sealant Glazing Applications.

Viracon offers a Deflection and Sightline Reference Guide to assist in identifying the appropriate sightline based on glass size and load. For products not identified on the chart, contact Viracon for sightline requirements specific to your project.

Glass Handling and Storage

Care needs to be taken during handling and glazing to ensure that glass damage does not occur. Do not allow glass edges to contact the frame or any hard surface during installation. Use rolling blocks if the insulating units are rotated or “cartwheeled” on their corners. To see an example of a rolling block, refer to the Glass Association of North America (GANA) glazing manual.

Improper glass storage techniques may result in damage to glass components, glass surfaces, coatings or glass breakage. Store glass crates properly to prevent them from tipping. Also, ensure proper blocking and protection from outside elements. Improper air circulation for spandrel glass may result in glass damage or staining. Refer to Viracon’s Glass Staining Tech Talk for additional information on glass staining and storage.

Viracon recommends a 5-7° lean against two wide, sturdy uprights, which are capable of withstanding crate weight.

Insulating glass units produced by Viracon with a pressure-compensated spacer must deliver to project elevation within 12 months. Insulating glass units with capillary tubes must be sealed as soon as possible upon arrival at project elevation.

Once the glass is installed, the architect, general contractor or building owner should provide for glass protection and cleaning. Weathering metals, alkaline materials or abrasive cleaners may cause surface damage. Windblown objects, welding sparks or other material that contacts the glass surface during construction may cause irreversible damage.

Failure to follow Viracon’s Glazing Guidelines voids Viracon’s standard limited warranties available at www.viracon.com.

Maintenance and Cleaning

Please refer to Viracon's Glass Cleaning and Maintenance Recommendations

Glass Strength and Breakage

It is important to first determine appropriate loads for the glass. Viracon can supply architects with glass strength analyses on specified products. "Unexplained" glass breakage may still occur due to thermal stress, glazing system pressures, glazing damage, handling and storage conditions, excessive wind loads, objects and debris striking the glass, improper factory fabrication or damage by persons or objects at the construction site.