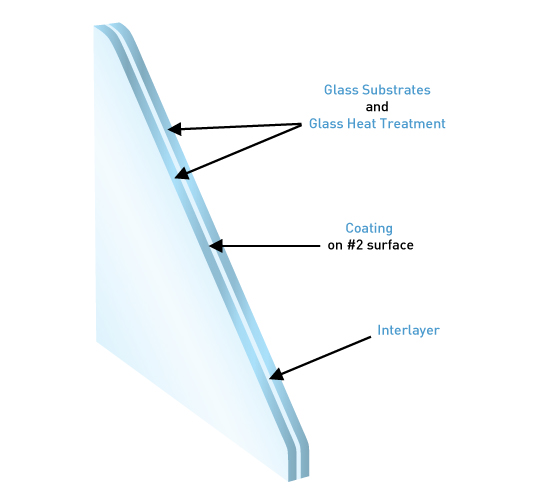

Viracon Laminated Glass features an interlayer bonded between two or more glass plies using heat and pressure.

The most common laminated glass units are constructed with two plies of glass permanently bonded together with one or more interlayers.

The glass plies may be of equal or unequal thickness. Laminated glass is a durable, high-performance glazing product, designed to remain integral in the opening should glass damage occur.

Often laminated glass is required to provide protection against man-made threats or natural disasters such as hurricanes, bomb blasts or forcible-entry.

For additional information regarding the interlayers Viracon offers, please refer to the interlayer component page.

Benefits of Laminated Glass

The most important characteristics of laminated glass are fall-out protection due to the ability of the interlayer to support and hold the glass when broken as well as the reduced ability to penetration the opening. The ability to resist various kinds of penetration is dependent upon a number of factors including thickness of the glass and the type of interlayer selected. For additional information regarding the interlayers Viracon offers, please refer to the interlayer component page. Viracon's architectural laminated glass products with a minimum .030" pvb interlayer comply with ANSI Z97.1-1984 and CPSC 16 CFR 1201, which are the industry safety standards for glazing materials.

Additionally, Viracon's laminated glass is available in various configurations for commercial glazing applications. To provide a wide array of design options, as well as meet various performance levels, Viracon's laminated glass can feature any combination of tinted glass substrates, high-performance coatings, printed patterns and pigmented interlayers. Laminated glass also offers a greater availability of coatings than monolithic glass. Low-E coatings which cannot be exposed, and therefore cannot be used with monolithic glass, can be used inside a laminated unit where they are protected.

Compared to monolithic glass, laminated glass units also have more aesthetic possibilities. The interlayers used in laminated glass are available in a variety of colors and opacities. In addition, the Low-E coating and silk-screen pattern, if desired, are applied to the exterior ply of glass leaving the interior ply available for additional treatment. For a spandrel location, a full coverage opaque ceramic frit can be applied to the inner face (surface #4). For vision areas where daylight is desired but view through needs to be minimized, a translucent ceramic frit can be applied to the surface facing the airspace (surface #3).

Components and Enhancements

When specifying laminated glass for your project, it is important to select and clearly outline the configuration as well as each individual component of the insulating glass unit.

In addition, Viracon offers many items to enhance the appearance and performance of insulating glass units for your building.